Danh Mục Sản Phẩm

-

DACO Kiến thức-Bài viết

DACO Kiến thức-Bài viết

-

DACO Giải Pháp

DACO Giải Pháp

-

DACO Sản Phẩm

DACO Sản Phẩm

-

Patlite

Patlite

- Đèn Còi Ưu Tiên Patlite

- Đèn Báo Patlite

- Đèn Báo Có Loa Patlite

- Đèn Tháp Patlite

- Đèn Tháp Có Loa Patlite

- Đèn Tháp LAN-USB

- Đèn Tháp Không Dây

- Đèn LED Chiếu Sáng

- Đèn Còi Phòng Nổ

- Loa Còi Patlite

- Phụ Kiện Patlite

- Hình Ảnh Thực Tế Patlite

- Tài Liệu-Phần Mềm Patlite

-

Qlight

Qlight

- Đèn Còi Ưu Tiên Qlight

-

Đèn Báo Qlight

- Đèn Báo Qlight Φ50

- Đèn Báo Qlight Φ60

- Đèn Báo Qlight Φ70

- Đèn Báo Qlight Φ80

- Đèn Báo Qlight Φ100

- Đèn Báo Qlight Φ125

- Đèn Báo Qlight Φ150

- Đèn Báo Qlight Φ180

- Đèn Báo Qlight Φ200

- Đèn Báo Có Loa Qlight

- Đèn Báo Có Loa MP3 Qlight

-

Đèn Báo Gắn Tường Qlight

- Đèn Báo Gắn Tường Qlight S60ADB

- Đèn Báo Gắn Tường Qlight S60ADL

- Đèn Báo Gắn Tường Qlight S60ADS

- Đèn Báo Gắn Tường Qlight S80AR

- Đèn Báo Gắn Tường Qlight S80AU

- Đèn Báo Gắn Tường Qlight S80AL

- Đèn Báo Gắn Tường Qlight S80ADR

- Đèn Báo Gắn Tường Qlight S80ALR

- Đèn Báo Gắn Tường Qlight S80AS

- Đèn Báo Gắn Tường Qlight QAD

- Đèn Báo Đa Màu Qlight

- Đèn Báo Đa Chức Năng Qlight

- Đèn Báo Năng Lượng Mặt Trời Qlight

- Đèn Báo Không Qlight

- Đèn Báo LAN-USB

-

Đèn Tháp Qlight

- Đèn Tháp Qlight Φ25

- Đèn Tháp Qlight Φ30

- Đèn Tháp Qlight Φ35

- Đèn Tháp Qlight Φ40

- Đèn Tháp Qlight Φ45

- Đèn Tháp Qlight Φ50

- Đèn Tháp Qlight Φ56

- Đèn Tháp Qlight Φ60

- Đèn Tháp Qlight Φ70

- Đèn Tháp Qlight Φ80

- Đèn Tháp Qlight Φ100

- Đèn Tháp Qlight Loa Báo

- Đèn Tháp Qlight Loa MP3

- Đèn Tháp Qlight Vuông

- Đèn Tháp Gắn Tường

- Đèn Tháp Bán Nguyệt

- Đèn Tháp Qlight Tròn

- Đèn Tháp Qlight Đa Màu

- Đèn Tháp LAN-USB

-

Đèn Chiếu Sáng Qlight

-

Đèn LED Tủ Điện Qlight

- Đèn LED Chiếu Sáng Qlight QPL

- Đèn LED Chiếu Sáng Qlight QPLC

- Đèn LED Chiếu Sáng Qlight QPHL

- Đèn LED Chiếu Sáng Qlight QPHLC

- Đèn LED Chiếu Sáng Qlight QGL

- Đèn LED Chiếu Sáng Qlight QGLC

- Đèn LED Chiếu Sáng Qlight QEL

- Đèn LED Chiếu Sáng Qlight QELS

- Đèn LED Chiếu Sáng Qlight QELT

- Đèn LED Chiếu Sáng Qlight QELTS

- Đèn LED Chống Nước Qlight

- Đèn LED Chống Dầu Qlight

- Đèn LED Làm Việc Qlight

-

Đèn LED Tủ Điện Qlight

- Loa Còi Qlight

- Đèn Còi Hàng Hải

- Đèn Còi Phòng Nổ

- Công Tắc Hành Trình

- Thiết Bị Không Dây Qlight

- Phụ Kiện Qlight

- Hình Ảnh Qlight

- Chứng Chỉ Qlight

- Tài Liệu-Phần Mềm Qlight

-

Đèn Còi Báo

Đèn Còi Báo

-

Đèn Còi Ưu Tiên

Đèn Còi Ưu Tiên

-

Beijer

Beijer

- Màn hình HMI Beijer

- Màn Hình IPC-EPC Beijer

- Máy Tính IPC-EPC Beijer

- Bộ Điều Khiển PLC Beijer

- Chuyển Đổi Giao Thức Beijer

- Hình Ảnh Thực Tế Beijer

- Tài Liệu-Phần Mềm Beijer

- CloudVPN Beijer

-

Weintek

Weintek

- HMI Weintek

- IPC Weintek

- cMT Weintek

- cMT-X Weintek

- mTV Weintek

-

Phụ Kiện Weintek

Phụ Kiện Weintek

- Giải Pháp-Ứng Dụng Weintek

- Hình Ảnh Thực Tế Weintek

- Tài Liệu Phần Mềm Weintek

-

Proface

Proface

- HMI Proface PS5000

- HMI Proface ST6000

- HMI Proface STM6000

- HMI Proface GP4000

- HMI Proface GP4000M

- HMI Proface GP3000

- HMI Proface GP2000

- HMI Proface GP77-GP70

- HMI Proface ST3000

- HMI Proface LT3000

- HMI Proface LT4000M

- HMI Proface SP5000

- HMI Proface SP5000X

- HMI PROFACE GC4500

- Phụ Kiện Proface

- Hình Ảnh Thực Tế Proface

- Tài Liệu-Phần Mềm Proface

-

HMI-IPC-MONITOR

HMI-IPC-MONITOR

-

Mitsubishi

Mitsubishi

-

Thiết Bị Tự Động Hóa

Thiết Bị Tự Động Hóa

-

Korenix

Korenix

-

ICP DAS

ICP DAS

-

Basler Camera

Basler Camera

-

Camera Vision

Camera Vision

-

Đèn Chiếu Camera

- LFine Đèn Chiếu Camera

- HighBright Đèn Chiếu Camera

- CST Đèn Chiếu Camera

-

TMS LITE ĐÈN CHIẾU CAMERA

- TMS Lite chiếu sáng trực tiếp

- TMS Lite chiếu sáng khuếch tán

- TMS Lite chiếu sáng gián tiếp

- TMS Lite chiếu sáng ngược

- TMS Lite chiếu sáng đồng trục

- TMS Lite chiếu sáng mô đun

- TMS Lite chiếu sáng tiêu điểm

- TMS Lite chiếu sáng chống nước IP65

- TMS Lite chiếu sáng quét dòng

- TMS Lite chiếu sáng 12v

- TMS Lite chiếu sáng RBGW

- TMS Lite chiếu sáng hồng ngoại

- TMS Lite chiếu sáng tia cực tím

- TMS Lite chiếu sáng kính hiển vi

- CCS - ĐÈN CHIẾU SÁNG CAMERA VISION

- Hikvision Camera

-

Đèn Chiếu Camera

-

Cognex Camera

Cognex Camera

-

Lmark Máy In

Lmark Máy In

-

Máy in-Đầu đọc

Máy in-Đầu đọc

-

MAX Máy In

MAX Máy In

-

Canon Máy In

Canon Máy In

-

Bepop Máy In

Bepop Máy In

-

Brother Máy In

Brother Máy In

-

Zebra Máy In

Zebra Máy In

-

Honeywell

Honeywell

-

Label Combi

Label Combi

-

Tepra Máy In

Tepra Máy In

-

Sato

Sato

-

Puty

Puty

-

-

Thiết bị đo

Thiết bị đo

-

Thủy Lực-Khí Nén

Thủy Lực-Khí Nén

-

OTHERS

OTHERS

-

Bơm Chân Không

Bơm Chân Không

-

Phụ kiện

Phụ kiện

Danh Mục Sản Phẩm

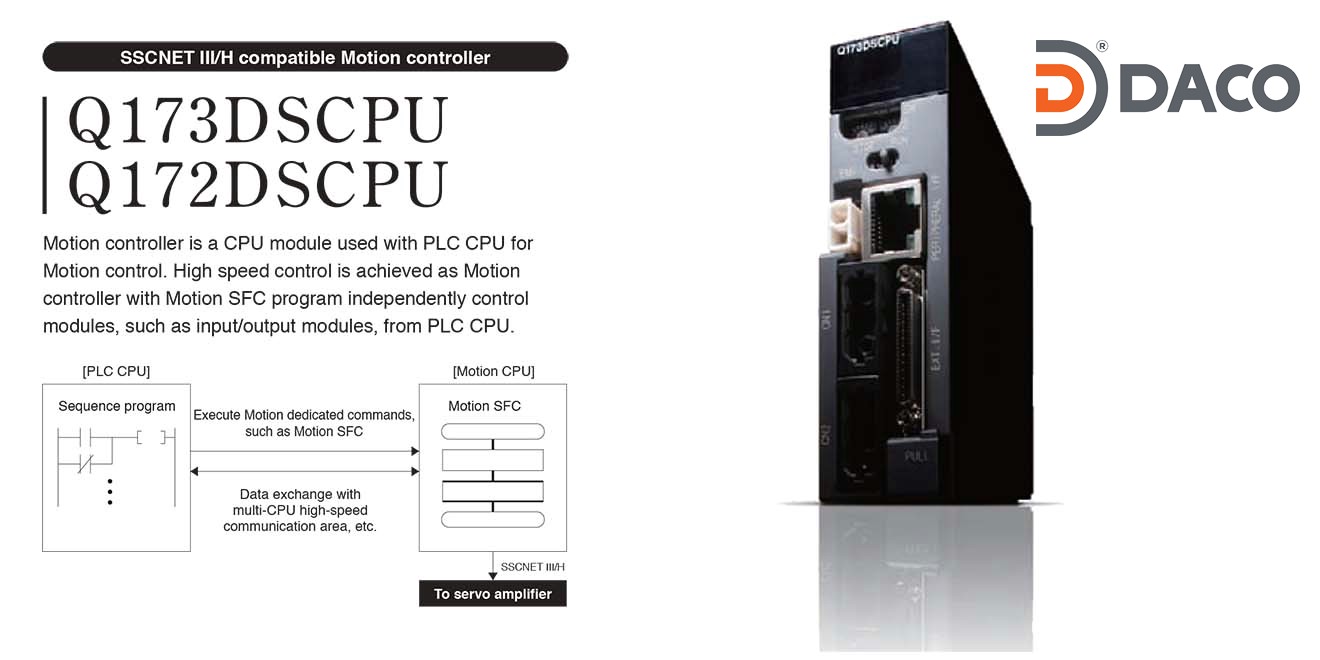

Q172DSCPU-Q173DSCPU Bộ điều khiển chuyển động Mitsubishi 16/32 trục SSCNET III/H

- Mã Sản Phẩm

- : Q172DSCPU-Q173DSCPU

- Tên Sản Phẩm

- : Q172DSCPU-Q173DSCPU Bộ điều khiển chuyển động Mitsubishi 16/32 trục SSCNET III/H

- Danh Mục

- : Servo Driver

- Thương Hiệu

- : Motion Controller Mitsubishi

- Giá

-

: Liên Hệ

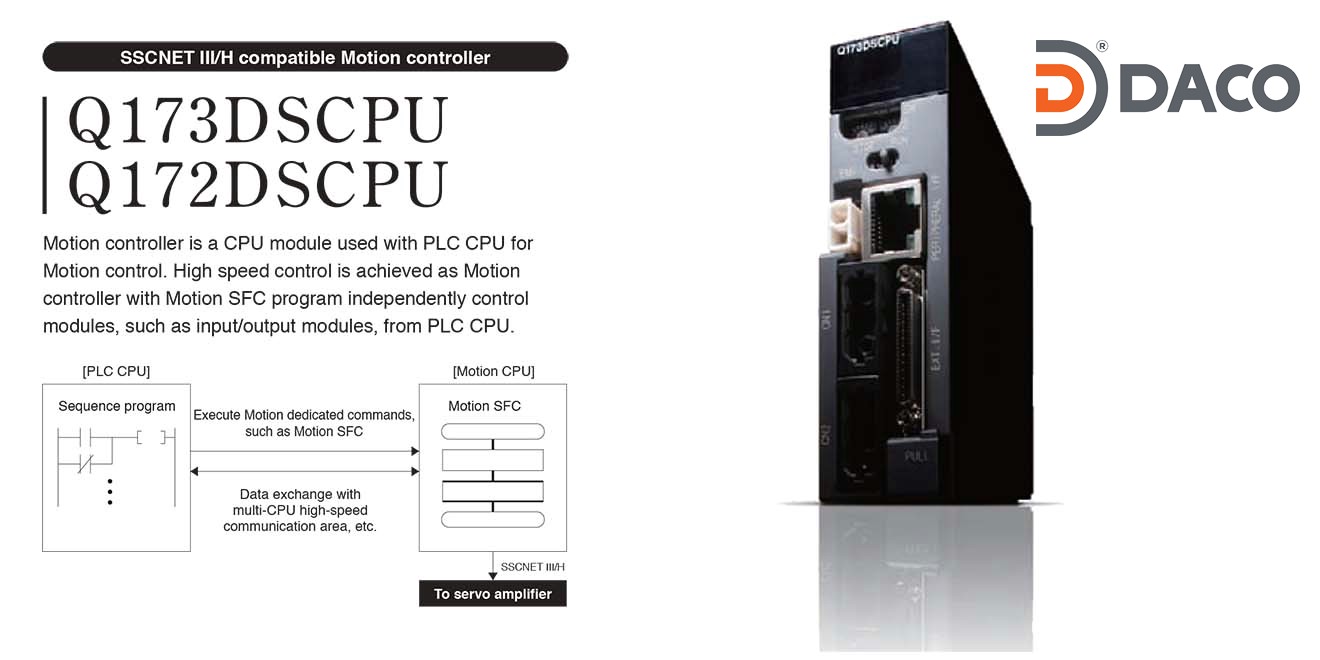

Q172DSCPU-Q173DSCPU Bộ điều khiển chuyển động Mitsubishi 16/32 trục SSCNET III/H

Chi Tiết Sản Phẩm

Q172DSCPU-Q173DSCPU Bộ điều khiển chuyển động Mitsubishi 16/32 trục SSCNET III/H

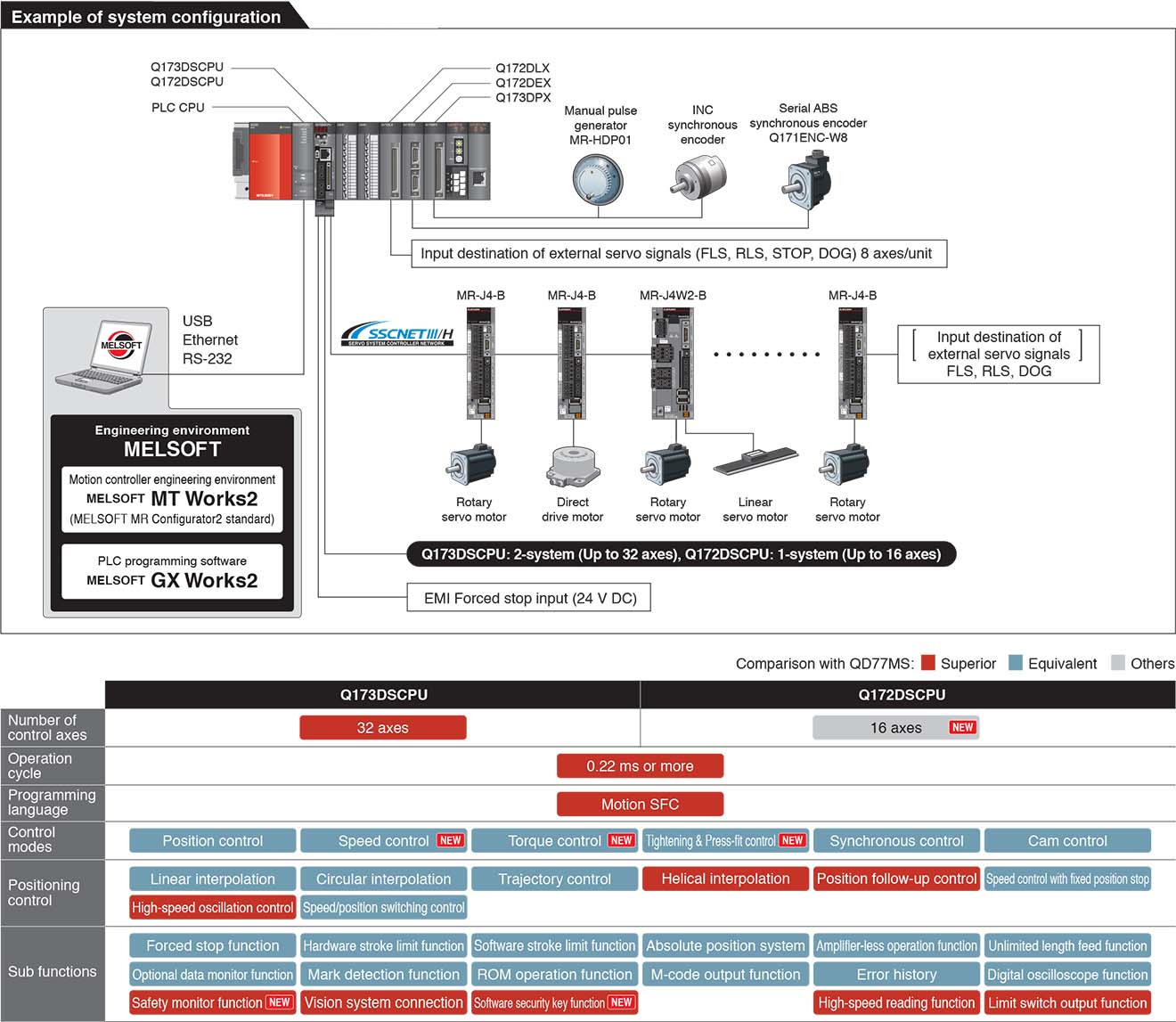

- Bộ điều khiển chuyển động là một mô-đun CPU được sử dụng với CPU PLC để điều khiển chuyển động. Điều khiển tốc độ cao đạt được như Bộ điều khiển chuyển động với chương trình Motion SFC điều khiển độc lập các mô-đun, chẳng hạn như mô-đun đầu vào / đầu ra, từ CPU PLC.

- Hỗ trợ kết nối điều khiển SSCNET III/H

- Q172DSCPU: Điều khiển 16 trục / 1 Line

- Q173DSCPU: Điều khiển 32 trục, 16 trục / 1 Line => 32 trục / 2 Line

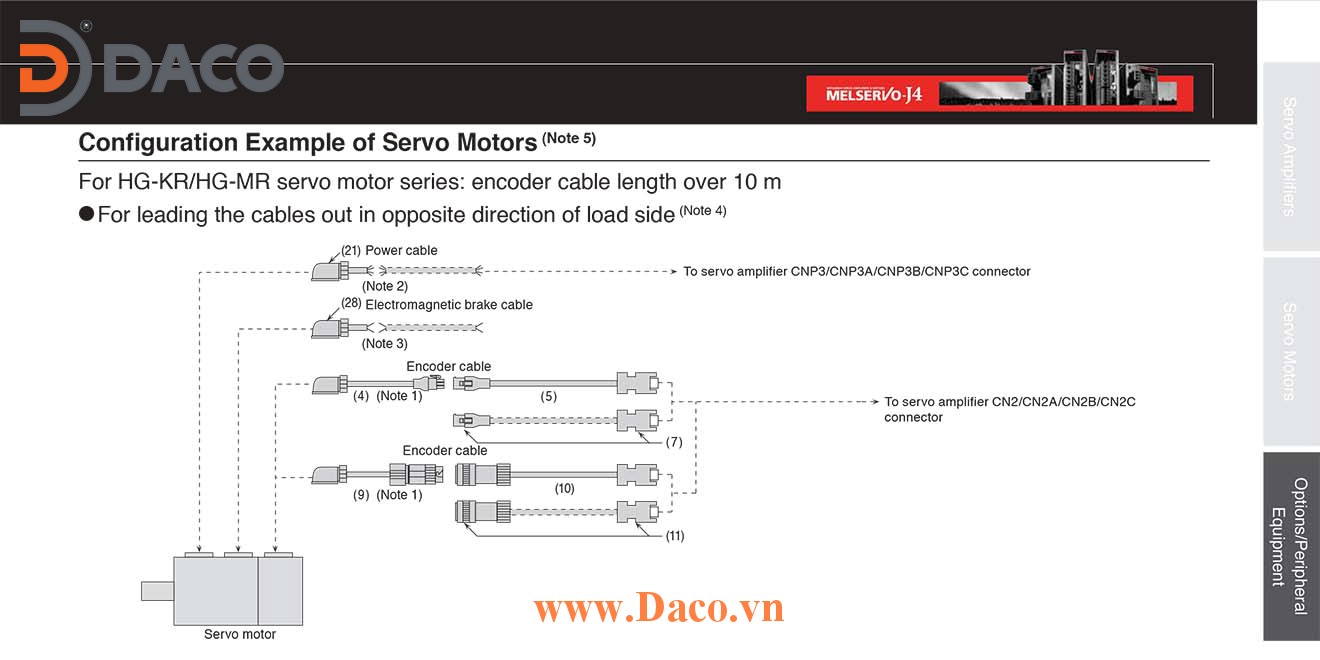

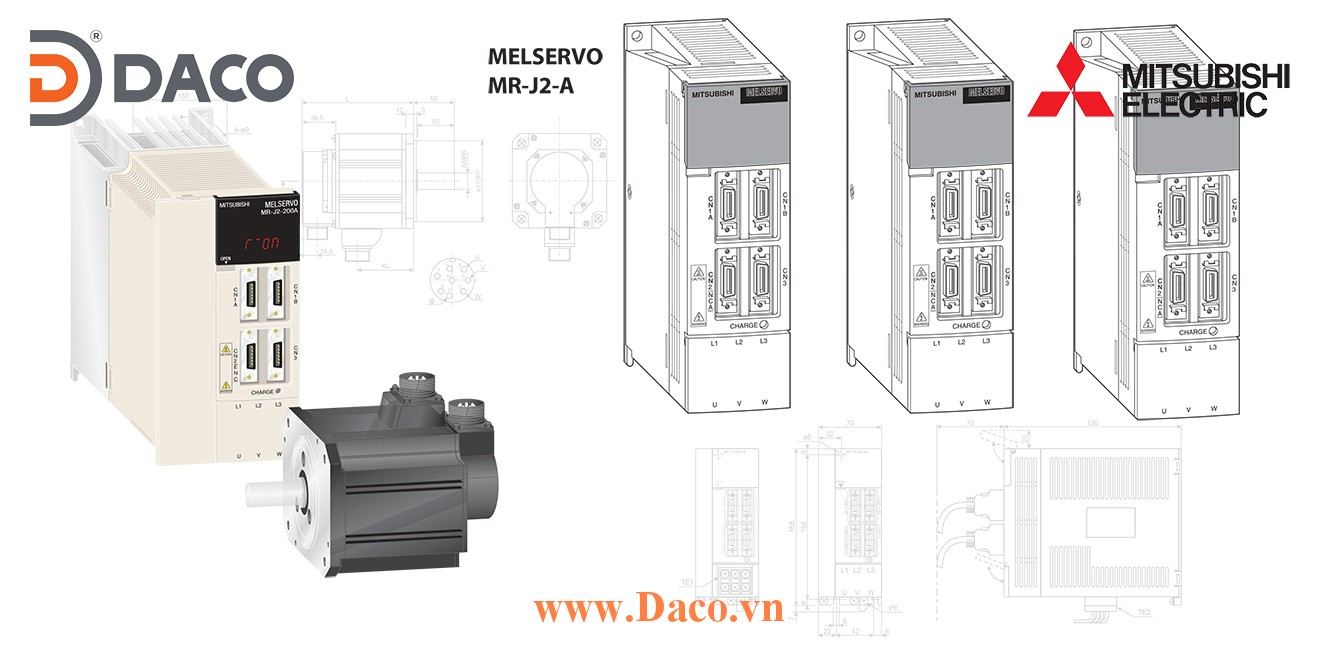

- Sử dụng cho bộ điều khiển động cơ Servo MR-J3-B, MR-J4-B

Thông số kỹ thuật:

| Item | Q173DSCPU | Q172DSCPU | |

| Number of control axes | Up to 32 axes | Up to 16 axes | |

| Operation cycle (default) |

SV13 | 0.22ms/ 1 to 4 axes 0.44ms/ 5 to 10 axes 0.88ms/ 11 to 24 axes 1.77ms/25 to 32 axes |

0.22ms/ 1 to 4 axes 0.44ms/ 5 to 10 axes 0.88ms/ 11 to 16 axes |

| SV22 | 0.44ms/ 1 to 6 axes 0.88ms/ 7 to 16 axes 1.77ms/17 to 32 axes |

0.44ms/ 1 to 6 axes 0.88ms/ 7 to 16 axes |

|

| Interpolation functions | Linear interpolation (Up to 4 axes), Circular interpolation (2 axes), Helical interpolation (3 axes) | ||

| Control modes | PTP(Point to Point) control, Speed control, Speed-position switching control, Fixed-pitch feed, Constant speed control, Position follow-up control, Speed control with fixed position stop, Speed switching control, High-speed oscillation control, Speed-torque control, Synchronous control (SV22 (Virtual mode switching method/Advanced synchronous control method)) |

||

| Acceleration/ deceleration control |

Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration, Advanced S-curve acceleration/deceleration | ||

| Compensation | Backlash compensation, Electronic gear, Phase compensation (SV22) | ||

| Programming language | Motion SFC, Dedicated instruction, Mechanical support language (SV22) (Note-1) | ||

| Servo program capacity | 16k steps | ||

| Number of positioning points | 3200 points (Positioning data can be designated indirectly) | ||

| Peripheral I/F | USB/RS-232/Ethernet (Via PLC CPU) PERIPHERAL I/F (Motion CPU) | ||

| Home position return function | Proximity dog method (2 types), Count method (3 types), Data set method (2 types), Dog cradle method, Stopper method (2 types), Limit switch combined method, Scale home position signal detection method, Dogless home position signal reference method, Driver home position return method |

||

| Home position return re-try function provided, home position shift function provided | |||

| JOG operation function | Provided | ||

| Manual pulse generator operation function | Possible to connect 3 modules (Q173DPX use) Possible to connect 1 module (Built-in interface in Motion CPU use) (Note-3) |

||

| Synchronous encoder operation function (Note-4) | Possible to connect 12 module (SV22 use) (Q172DEX + Q173DPX + Built-in interface in (Note-5) + Via servo amplifier (Note-5), (Note-6) + Multiple CPU synchronous control (Note-5)) |

||

| M-code function | M-code output function provided, M-code completion wait function provided | ||

| Limit switch output function | SV13 | Number of output points 32 points Watch data: Motion control data/Word device |

|

| Limit switch output function | SV22 | Virtual mode switching method: Number of output points 32 points Advanced synchronous control method: Number of output points 64 points ´ 2 settings Output timing compensation Watch data: Motion control data/Word device |

|

| ROM operation function | Provided | ||

| Multiple CPU synchronous control (Note-5) | Provided | ||

| External input signal | Q172DLX, External input signals (FLS/RLS/DOG) of servo amplifier, Built-in interface in Motion CPU (DI), Bit device |

||

| High-speed reading function (Note-7) |

Provided (Via built-in interface in Motion CPU, Via input module, Via tracking of Q172DEX/Q173DPX) |

||

| Forced stop | Motion controller forced stop (EMI connector, System setting), Forced stop terminal of servo amplifier | ||

| Number of I/O points | Total 256 points (Built-in interface in Motion CPU (Input 4 points) + I/O module + Intelligent function module) |

||

| Mark detection function | Mark detection mode setting | Continuous detection mode, Specified number of detection mode, Ring buffer mode | |

| Mark detection signal | Built-in interface in Motion CPU (4 points), Bit device, DOG/CHANGE signal of Q172DLX | ||

| Mark detection setting | 32 settings | ||

| Clock function | Provided | ||

| Security function | Provided (Protection by software security key or password) |

||

| All clear function | Provided | ||

| Remote operation | Remote RUN/STOP, Remote latch clear | ||

| Optional data monitor function | SSCNET III /H | Up to 6 data/axis (Communication data: Up to 6 points/axis) |

|

| SSCNET | Up to 3 data/axis (Communication data: Up to 3 points/axis) |

||

| Digital oscilloscope function | Motion buffering method (Real-time waveform can be displayed) Sampling data: Word 16CH, Bit 16CH |

||

| Absolute position system | Made compatible by setting battery to servo amplifier. (Possible to select the absolute data method or incremental method for each axis) |

||

| SSCNET communication (Note-8) |

Communication type | SSCNET III /H, SSCNET | |

| Number of lines | 2 lines (Note-9) | 1 line (Note-9) | |

| Driver communication function (Note-10) |

Provided | ||

| Number of Motion related modules | Q172DLX | 4 modules usable | 2 modules usable |

| Q172DEX | 6 modules usable | ||

| Q173DPX | 4 modules usable (Note-11) | ||

| Number of SSCNET III /H head module connection stations | Up to 8 stations usable (Up to 4 stations/line) |

Up to 4 stations usable | |

| Number of optical hub unit connections | Up to 32 units usable (Up to 16 units/line) |

Up to 16 units usable | |

Sản Phẩm Liên quan

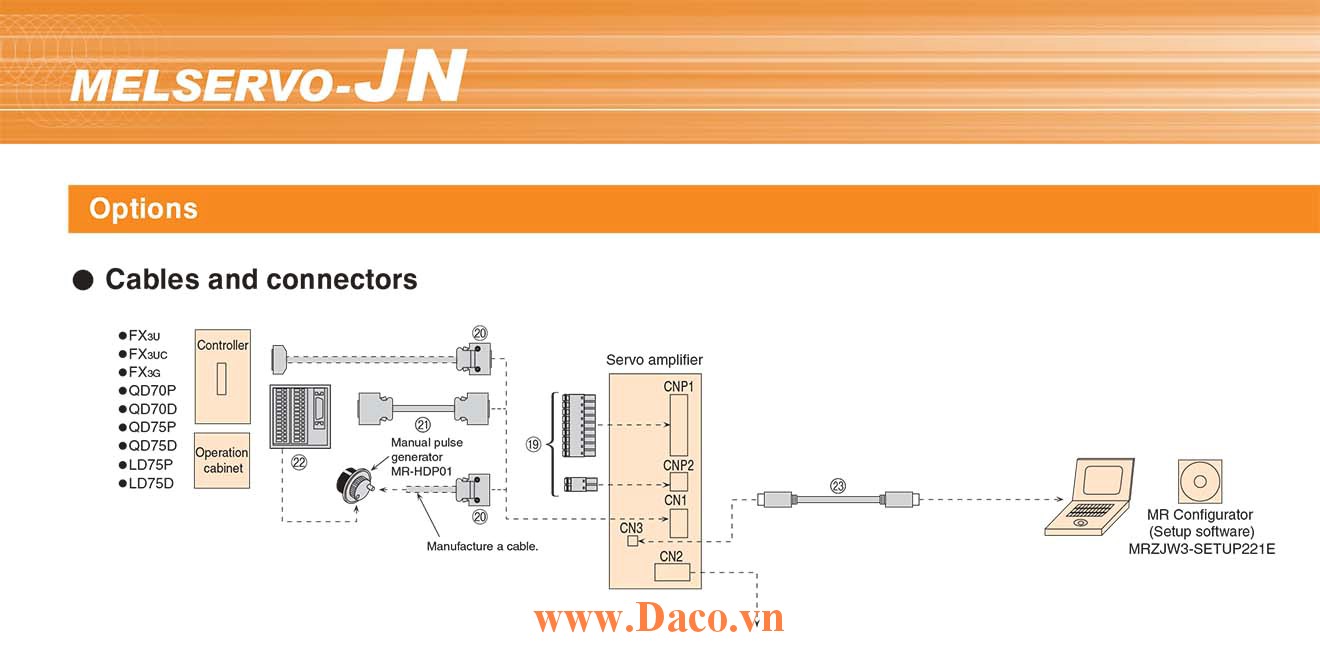

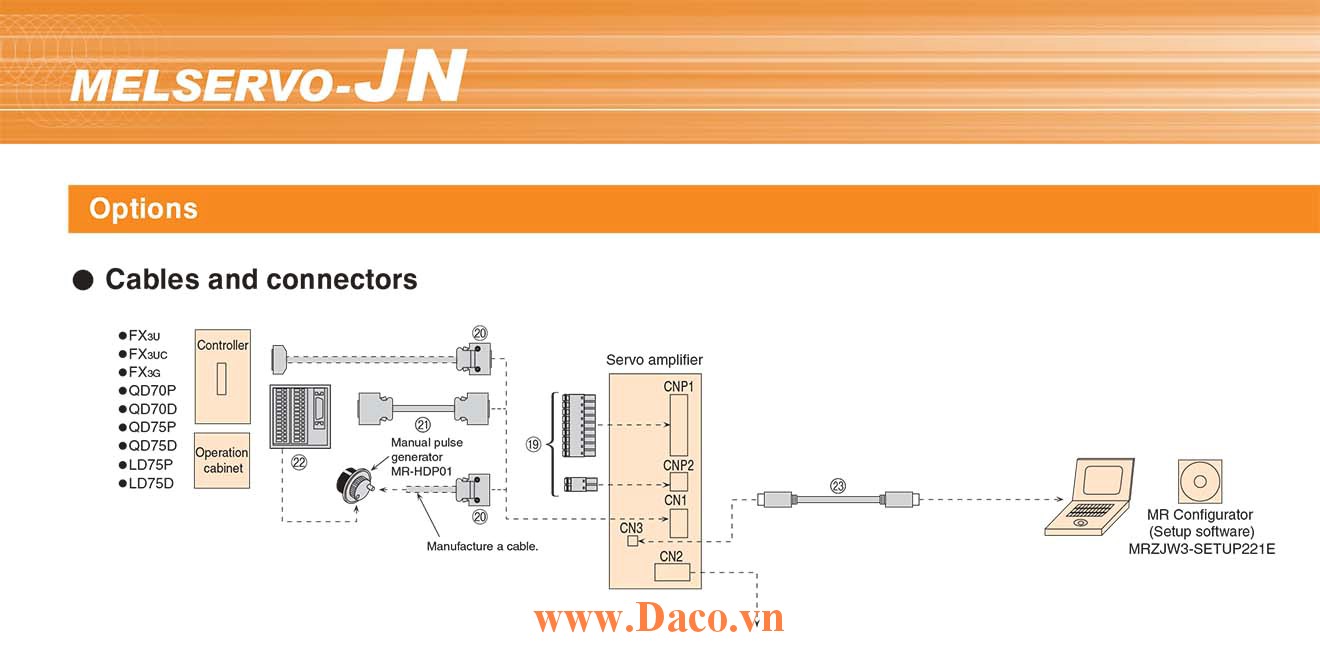

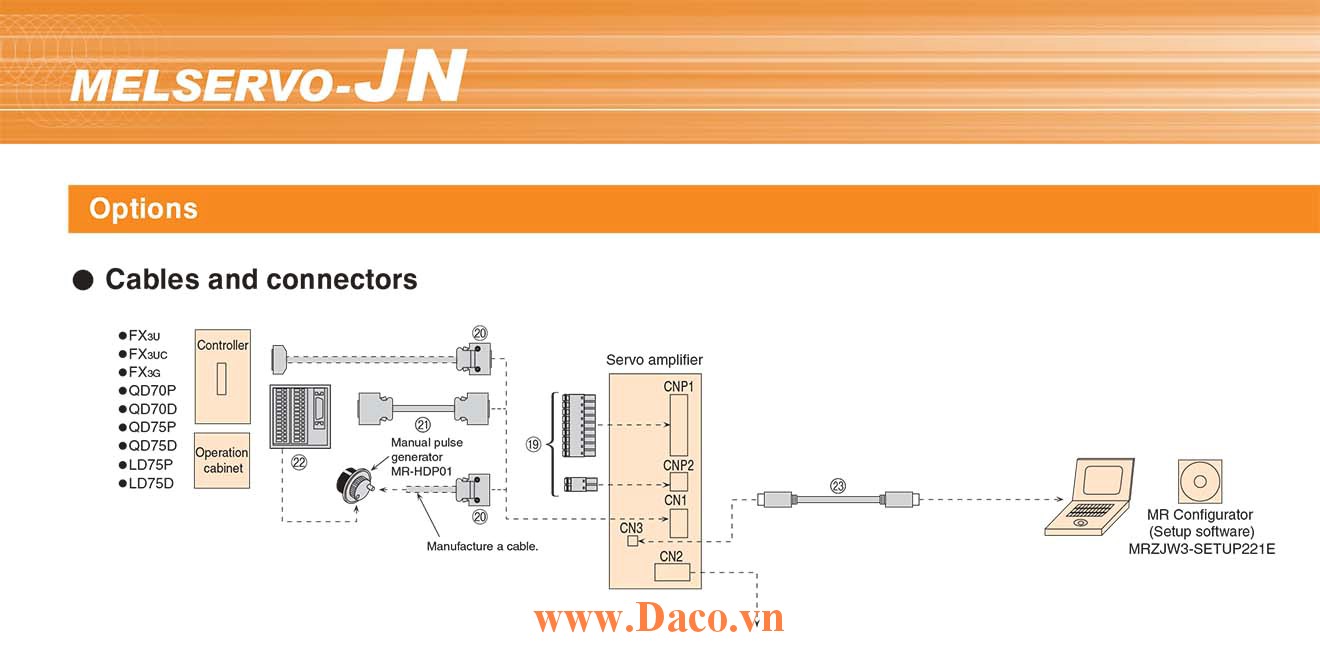

MR-JN Cáp Phanh-Bộ điều khiển Mitsubishi Servo Driver Amplifier

Liên Hệ: 0359206636

MR-JN Cáp Nguồn-Bộ điều khiển Mitsubishi Servo Driver Amplifier

Liên Hệ: 0359206636

MR-JN Cáp Encoder-Bộ điều khiển Mitsubishi Servo Driver Amplifier

Liên Hệ: 0359206636

MR-JN Bộ điều khiển động cơ Servo Mitsubishi 0.1 KW~0.4 KW, 1 Pha 220VAC/110VAC

Liên Hệ: 0359206636

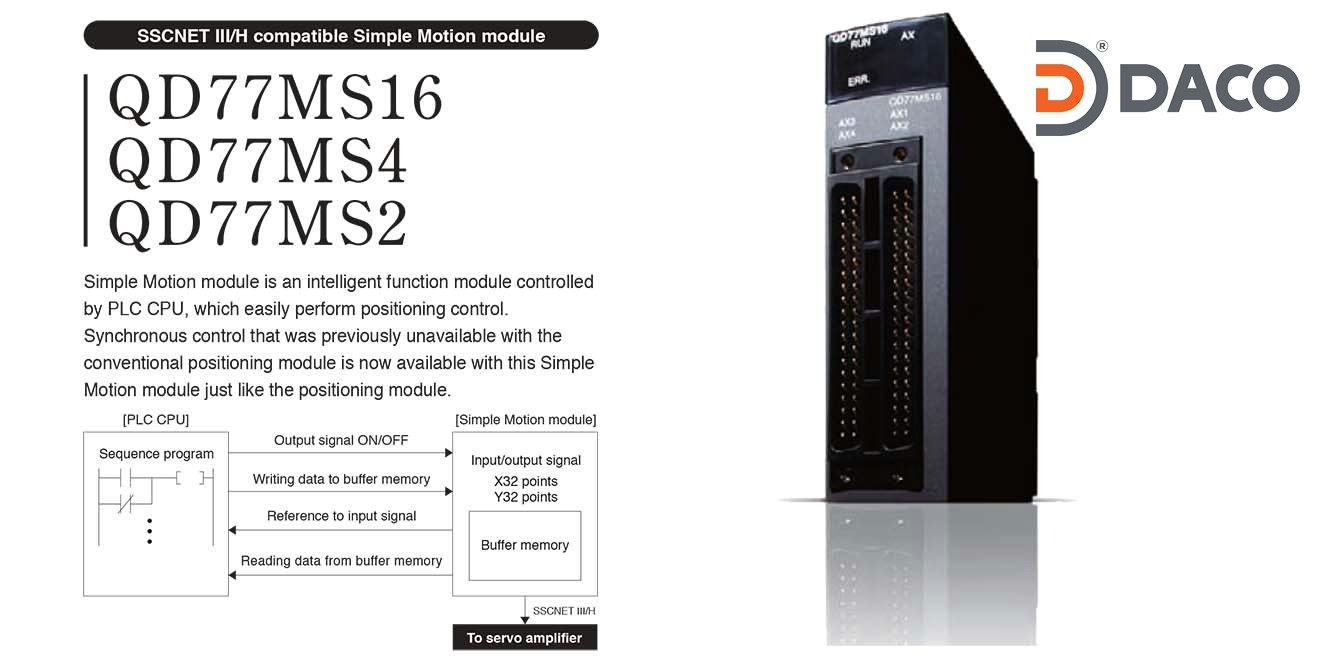

QD77MS Module điều khiển chuyển động Mitsubishi 2/4/16 trục SSCNET III/H

Liên Hệ: 0359206636

Q172DCPU-Q173DCPU Bộ điều khiển chuyển động Mitsubishi 8/32 trục SSCNET

Liên Hệ: 0359206636

MR-J4 Cable Connector-Bộ điều khiển Mitsubishi Servo Driver Amplifier

Liên Hệ: 0359206636

MR-J2S-A4 Bộ điều khiển Servo Driver Mitsubishi 3 Pha hoặc 380 VAC

Liên Hệ: 0359206636

Tin Mới

Sản Phẩm Nổi Bật

Triển khai hệ thống quản lý sản xuất SEEACT-MES tại nhà máy bao bì Tân Long

Liên Hệ: 0359206636

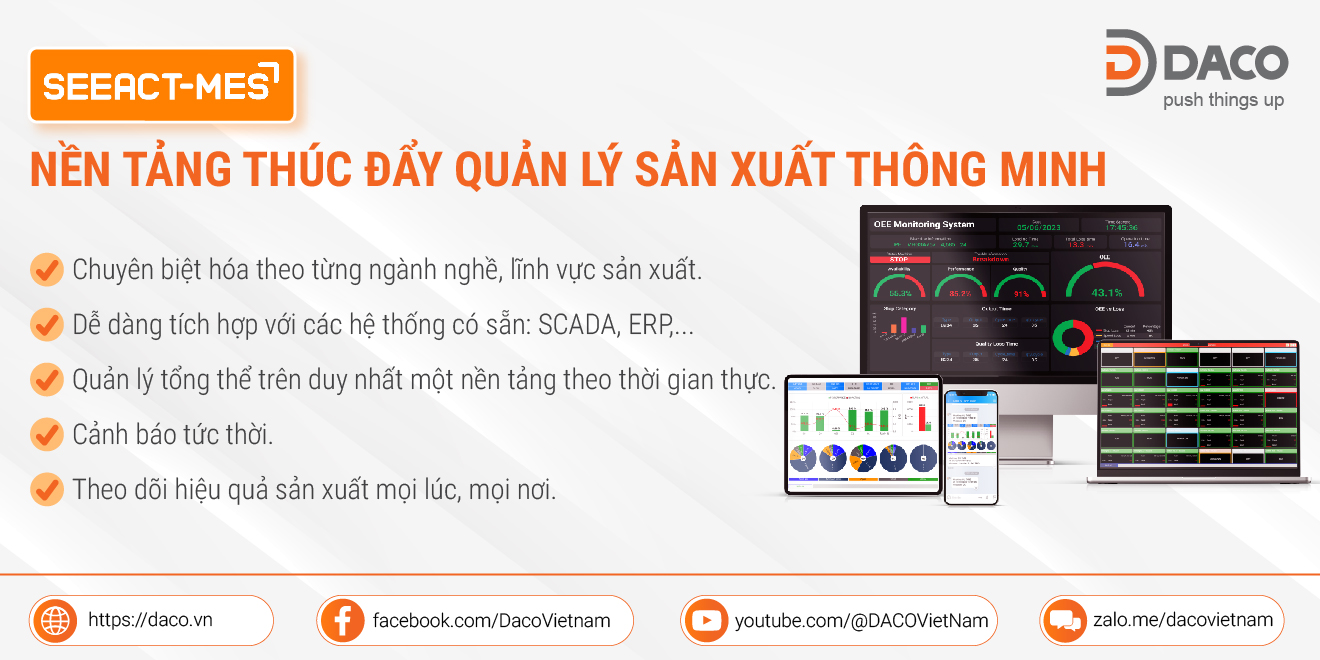

SEEACT-MES hệ thống quản lý sản xuất chuyên sâu & toàn diện #01 Việt Nam

Liên Hệ: 0359206636

Triển khai hệ thống quản lý sản xuất SEEACT-MES tại nhà máy bao bì Châu Thái Sơn

Liên Hệ: 0359206636

Giải pháp quản lý kho bằng mã vạch - Chìa khóa giảm thiểu thất thoát và lãng phí

Liên Hệ: 0359206636

5 YẾU TỐ KHÔNG THỂ BỎ QUA KHI LỰA CHỌN HỆ THỐNG MES CHO NHÀ MÁY SẢN XUẤT

Liên Hệ: 0359206636

Hệ thống MES là gì? Tại sao MES không thể thiếu đối với doanh nghiệp sản xuất?

Liên Hệ: 0359206636

Giới Thiệu

- Tư Vấn Giải Pháp Kỹ Thuật - Mr. Vũ: 0936.064.289

- Hỗ trợ kỹ thuật - Mrs. Thúy: 0904.182.235

- Nhà máy-Mrs. Vân Nguyễn: 0902.189.622

- Máy In Nhãn - Mr. Vũ: 0936.064.289

- Máy In Ống Lồng - Mr. Duy Anh: 0902286498

- Màn Hình HMI - Mr. Duy Anh: 0902.286.498

- Đèn Loa Còi Báo - Mr. Minh: 0936.135.466

- Nhà máy-Mrs. Vân Phạm: 0903.496.598

- Vision Camera Barcode-Mrs. Thúy: 0904.182.235

- Về Chúng Tôi DACO

Quy Định & Chính Sách

Thông Tin Liên Hệ

Công Ty TNHH DACO - Nhà Cung Cấp Giải pháp Quản Lý Sản Xuất, Thiết Bị Tự Động Hóa Và Dịch Vụ Kỹ Thuật Công Nghiệp

Địa chỉ: Số 146, Đường Cầu Bươu, Xã Tân Triều, Huyện Thanh Trì, Thành Phố Hà Nội

Hotline: 0359.206.636 / 0936.13.5466

Email: kinhdoanh@dacovn.com

Website: www.daco.vn